06.

Print Industry

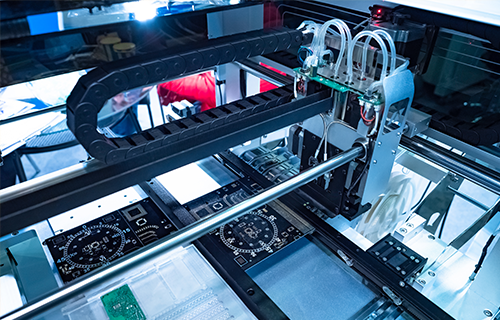

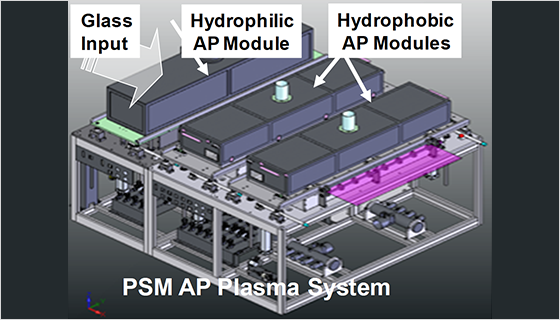

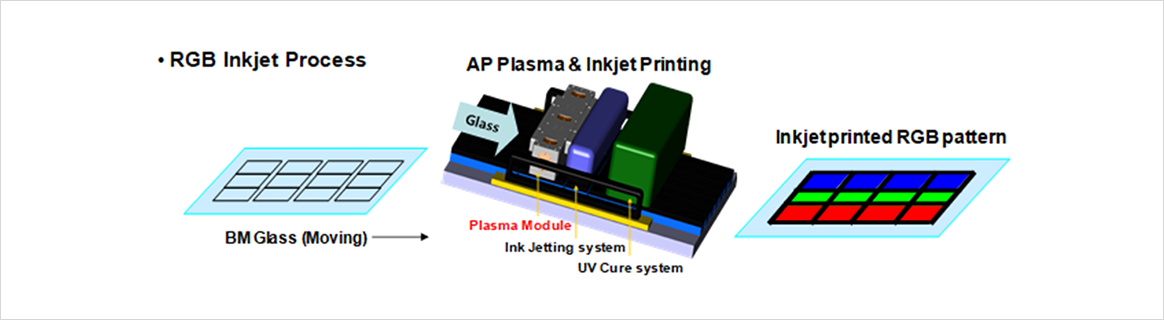

- - AP plasma is applied to OLED RGB /Quantum Dot Display inkjet process

- - AP plasma is applied to nano-imprinting pretreatment/primer removal process

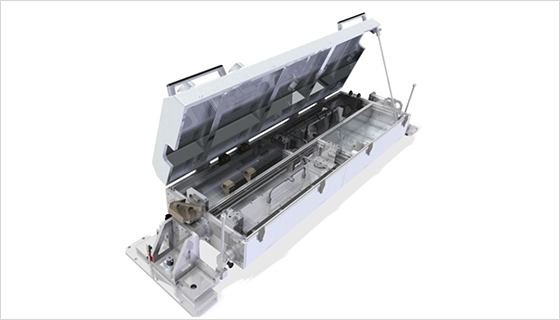

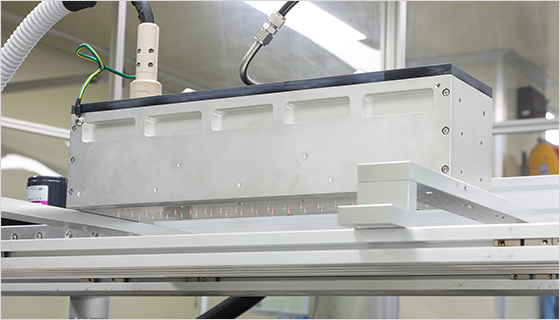

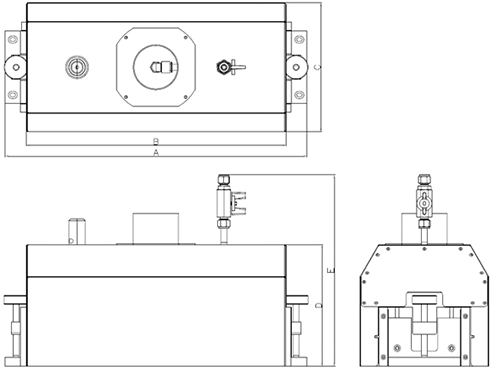

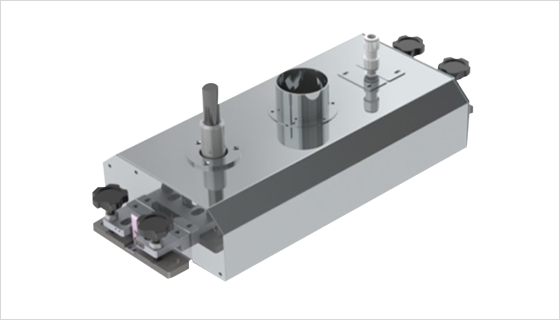

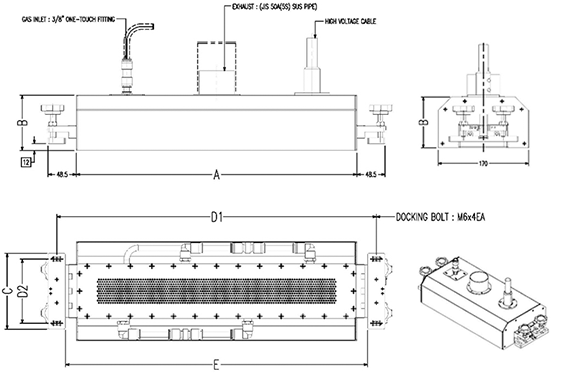

AP Plasma Electrode

- 1. Applied to the selective surface treatment process before inkjet printing for the OLED RGB Pattern /Quantum Dot Display

- 2. AP plasma is applied to the nano-imprinting pretreatment/primer removal processes

- 3. It can be stably applied to large samples (6~10G) as well (processing speed: 6-8m/min)